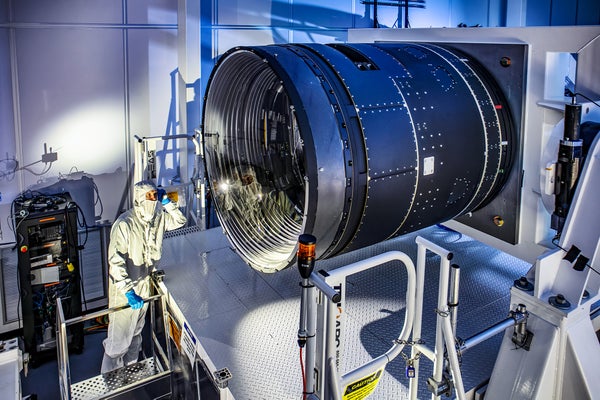

By late next year, if all goes to plan, the Vera C. Rubin Observatory will have started its 10-year survey of the solar system, Milky Way and galaxies beyond. Its giant eye on the southern skies is a 3.2-gigapixel camera with the size and weight of a small car. By mass and pixel resolution, it is the largest digital camera on Earth. It will scan the cosmos from atop a mountain called Cerro Pachón in northern Chile.

There is just one hitch: the delicate, nearly three-metric-ton machine is currently some 10,000 kilometers away in the hills above San Francisco Bay, where its builders have put it through final tests. In the coming weeks the precisely engineered camera will begin a tense intercontinental voyage in which it will be flown by cargo plane, hauled by truck and painstakingly escorted up twisty mountain roads.

The daunting logistics fall to members of an obscure but consequential engineering subfield dedicated to keeping multimillion-dollar astronomy hardware intact in transit. This is “a very obvious and visible moment when things can go wrong,” says engineer Margaux Lopez of the Rubin Observatory and the SLAC National Accelerator Laboratory, who is in charge of the effort.

On supporting science journalism

If you're enjoying this article, consider supporting our award-winning journalism by subscribing. By purchasing a subscription you are helping to ensure the future of impactful stories about the discoveries and ideas shaping our world today.

The Rubin camera’s journey begins in a clean room in Silicon Valley, where SLAC will outfit the camera with a steel-and-wire-rope exoskeleton. “It’s a frame sitting on springs on another frame, essentially,” says SLAC and Rubin engineer Martin Nordby. This shield will keep the camera tucked within the confines of a standard shipping container and protect its delicate innards from vibrations. Then, over two days in May, SLAC personnel will drive the camera’s container and 49 crates of equipment to San Francisco International Airport, where everything will be packed aboard a chartered Boeing 747 cargo plane for the 16-hour flight to the Arturo Merino Benítez International Airport in Santiago, Chile.

The Rubin team is relatively lucky: parts of other telescopes in development, also bound for observatories under Chile’s exceptionally clear skies, must spend weeks traveling at sea. When the Fred Young Submillimeter Telescope sends its five-story-tall support structure—too large to fit into a freight aircraft—from Germany to Chile, it will have to do so via break-bulk cargo ship by way of Antwerp, Belgium.

The Extremely Large Telescope (ELT)’s giant mirrors are taking the ocean route from Europe to Chile, too. “Historically..., we shipped mostly everything by plane, but with the new type of sizes we’re talking about with the ELT, planes either are not big enough or the costs are ridiculously high,” says Hervé Kurlandczyk, an engineer for the European Southern Observatory, who works on ELT and isn’t involved with the Rubin project.

Physical damage is always a threat, no matter the route or mode of transport. Astronomy, by design, requires some of the most delicate components in the world. Anything from bumps in the road to turbulence in the air can rattle sensitive electronics or jostle painstakingly placed parts out of alignment. Mirrors, including Rubin’s pieces that arrived in Chile in 2019, may require refrigeration and humidity controls or risk damage to their coating.

Transit brings other possible headaches that are familiar to anyone experienced in international shipping. Bad weather and other snafus can redirect or stall transports. Several years ago miscommunication caused the container ship carrying part of the Simons Observatory to sit at anchor for two weeks off Chile, leaving observatory staff scratching their head in port. Even observatories need to clear customs, especially when exiting the U.S.; astronomical instruments made in the U.S. may, for example, run into government export controls designed to keep advanced optical technology within the country’s borders.

All these worries mean engineers try “to control, as much as possible, every single step of the whole chain,” Kurlandczyk says. Although Santiago is on the other side of the equator from San Francisco, SLAC will continue to oversee the camera’s transit within Chile. Once the 747 lands, its cargo will be loaded into a caravan of nine vehicles—each similar to the curtain-side trucks used to transport beverages and outfitted with air-ride suspensions for additional protection from vibrations. The caravan’s six-hour road trip to the base of Cerro Pachón will be a prelude to the most arduous part of the voyage: getting the camera from the base of the mountain to the observatory atop one of its peaks.

Rubin Observatory/NOIRLab/NSF/AURA/H. Stockebrand (CC BY 4.0)

This last leg will be a 35-kilometer journey up a winding snake of dirt roads and switchbacks. It will be narrow and perilous, and the observatory at the top won’t be able to receive more than one truck at a time, so the process will take three days, with three trucks per day. And the truck carrying the camera itself, escorted in front and behind by observatory vehicles, will be able to travel no faster than 10 kilometers per hour. Lopez says the camera’s ascent will take five hours to make a trip that takes most other cargo about 90 minutes.

Lopez and her colleagues can take some comfort in the fact that they’ve already practiced almost every step of the trip using dummies with the same mass as the telescope parts. They’ve loaded these weights into trucks driven up and down the freeways of the San Francisco Peninsula and along Chilean roads; they’ve even rehearsed the flight from California to Chile.

“Every time we handle something, it’s essentially the first time it’s ever been done,” Lopez says. “We’ve spent a lot of effort to figure out ways to practice these delicate procedures with something that is not as fragile before we do it with, you know, $25-million optics.”

More than five years of preparation have gone into the camera’s six-day journey. “This has to work. It has to be successful. We cannot break anything along the way or lose anything or—pick your favorite failure mode,” Lopez says. “But we have a really solid logistics plan, and we’re ready to go.”